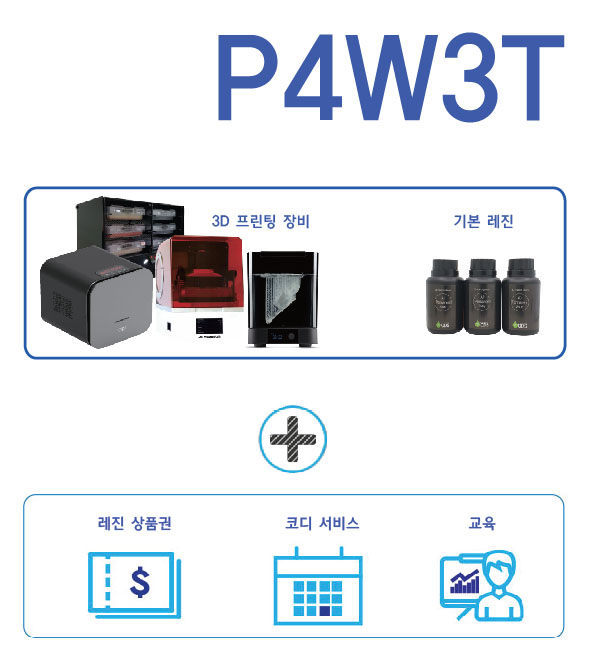

Products

C&B Temporary

The dental polymer material

for producing temporary prostheses

such as crowns & bridges

until the permanent restoration is completed

KFDA, CE Certification / FDA in Process

Additional information

| Weight | 1 kg |

|---|---|

| Dimensions | 130 × 125 × 130 cm |

| Resin Consumption | About 1,000ea(Based on 1 kg) |

Description

C&B Temporary – Resin for temporary crown

Unit

- Unit : Bottle(250g) / Box(1kg)

- Shipment Unit : 1kg (4 bottles), 2kg (8 bottles), 4kg (16 bottles), 10kg (40 bottles)

- Bottle Size : ø 63 x 120 mm

- Box Size : 133 x 133 x 130 mm

Features

- 3D printer for dentistry only

- Excellent mechanical properties (high flexural and tensile strength)

- It is a resin for temporary crown and can be used for up to 30 days

- Realization of brightness of natural teeth

- Securing stability against torsion, contraction and expansion

- Sophisticated, accurate output

- Soft smell

Output Conditions in 3D Printer

- Light Source : UV LED

- Wavelength : 405 nm

- Layer Thickness : 100 ㎛

- Resin Curing Energy When Printing : 11~15mJ/㎠

Curing Conditions in Curing Machine(Cure-Box)

- Light Source : UV LED

- Wavelength : 395~405 nm

- Full Curing Energy After Printing : 174,000~243,600mJ/㎠ (5~7min in Cure-Box) (Curing twice for 7 minutes each for LED lifespan)

1. PROPERTIES OF 3D PRINTING RESIN

| Properties | Value | Remark |

| Color | Ivory | |

| Viscosity | 300 ± 100 cPs @ 23℃ |

2. PROPERTIES OF 3D PRINTING PRODUCT

| Properties | 값 / value | 비고 / Remark |

| Color | Clear | |

| Rockwell's Hardness | ≥ HRR 120 | ISO 2039-2 |

| Flexural Strengt | ≥ 150 MPa | ISO 10477 |

| Flexural Modulus | ≥ 2,000 MPa | ISO 10477 |

3. 3D PRINTING CURING CONDITIONS

| Provision | Condition | Remark |

| Light Source | UV LED | |

| Wavelength | 405 nm | |

| Layer Thickness | 100 ㎛ | |

| UV energy | 12 ~ 16 mJ/cm2 | per 1 Layer |

| LED Power | 4.5 mW/cm2 | per 1 Layer |

| Exposure Time | 3.5 sec |

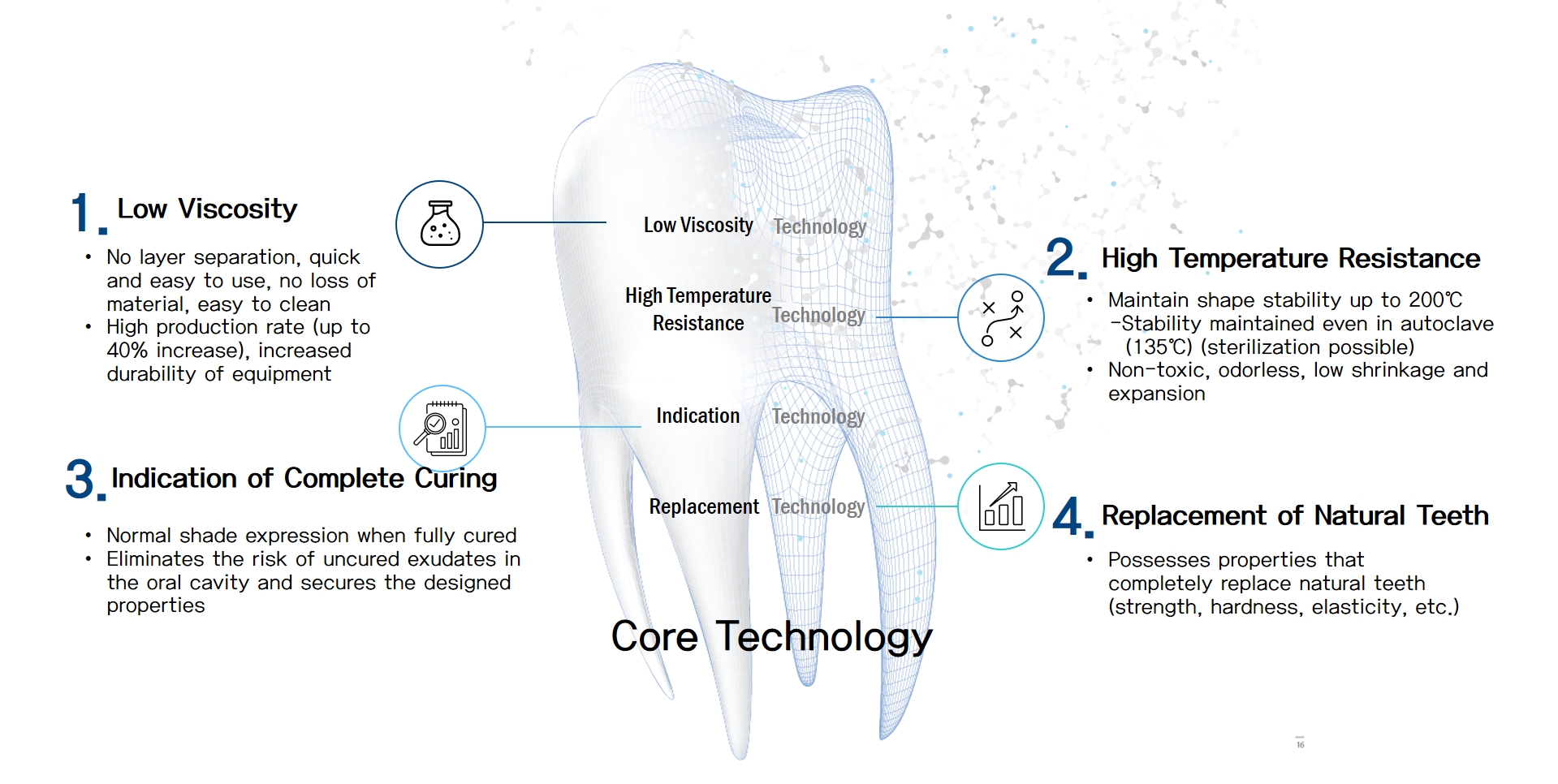

Futuristic Low-Viscosity Dental Material – ODS Resin

Advantages of ODS Dental Materials

- Low viscosity (1/10 to 1/14 level of viscosity compared to other resins)

- For dental 3D printer only (Both LCD and DLP methods are available)

- Realization of natural tooth color (Shade)

- Holds most of domestic and foreign certificates (KFDA, FDA, CE, ISO, GMP)

- Able to implement of sophisticated shapes (hexa structure, etc.)

- Odorless (no odor), no skin trouble

- Excellent mechanical properties (strength + elasticity) – Able to replace natural teeth of “Permanent” Resins

- Abundant clinical completion (For example, the world’s first clinical success for Modelless Direct Clear Aligner)

- High temperature sterilization (autogravable) possible at 135˚C (high heat resistance at 200˚C)

- No uncured extracts in the oral cavity (Fully cured or not can be identified)

Comparison of low/high-viscosity materials

| High viscosity materials (Other Reains) | Comparison of high/low-viscosity materials | Low viscosity materials (ODS Resins) |

| Damage to the properties due to layer separation of the material Need time and separate equipment (Mixer) for reuse | Layer separation | No layer separation, so easy to implement physical properties. Quick and easy to use! |

| Waste of materials due to a large amount of residue in containers, printouts, molding plates, and vat Difficult to clean containers, printouts, molding plates, and vat, wasting time and money | Loss of material | Almost no loss of resin and easy to clean as it leaves almost no residue! |

| Possible to print about 800~900 single crowns based on 1Kg. | Production rate | Possible to print about 1,000~1,200 single crowns based on 1Kg. |

| Cost increase due to frequent replacement by damage to the film, Decrease in equipment durability | Durability of equipment | Almost no damage to the film during printing! Minimize impact on durability of equipment! |

| Difficult to evacuate air bubbles in resin Influence the physical properties (strength) intended by the manufacturer | Air bubble phenomenon | Easy to release air bubbles in the resin, no effect on physical properties (strength) intended by the manufacturer! |

The 4 Core Technologies of ODS Resin

The development concept of ODS resin was first thoroughly started from the user’s point of view, and the core required properties were derived in consideration of the inconvenience of clinical reality and the user’s convenience. The 4 core technologies have been established from these core required properties, which are highly praised from all over the world. Currently, the 4 core technologies of ODS are applied to all resin product lines and are being produced.

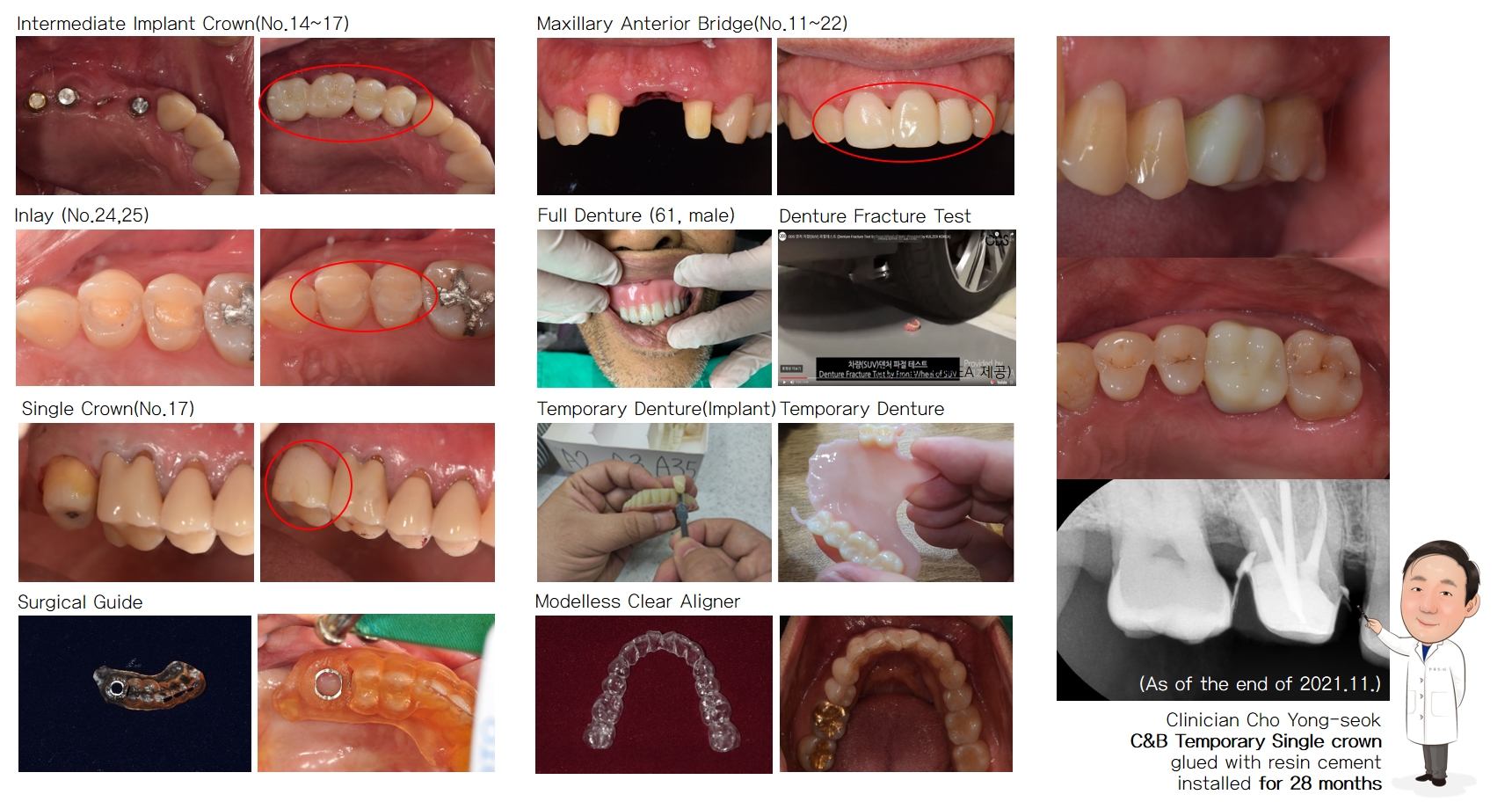

Clinical Applications of ODS resins

ODS resins, world-class products have already been released in each dental field, including permanent, denture and surgical guide, especially Modelless Direct Clear Aligner, which is a recent issue, and clinical appliances are actively in progress.

The goal of ODS dental material is the resin

that can completely replace natural teeth

Comparison between natural teeth and ODS resin

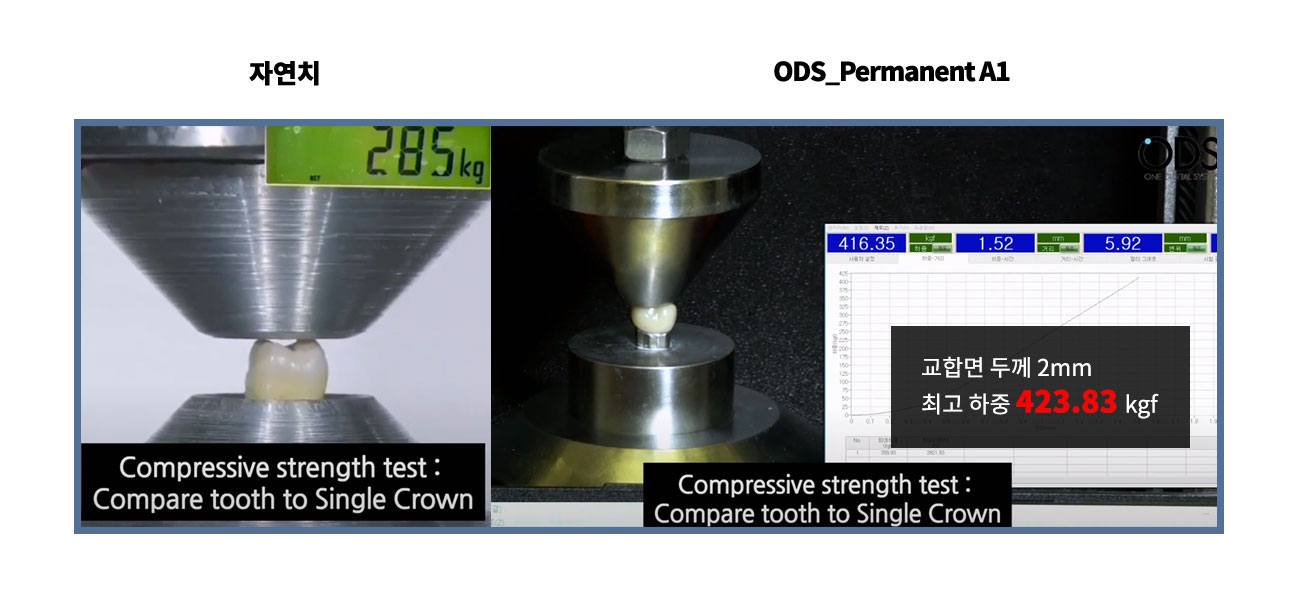

1) Compressive strength comparison / Permanent (Single Crown)

ODS Permanent resin is developed with the goal of completely replacing natural teeth and is implementing it. (strength 1.5 times, hardness 90%, Fracture Elongation Rate of 14.66% and elasticity higher than natural teeth)

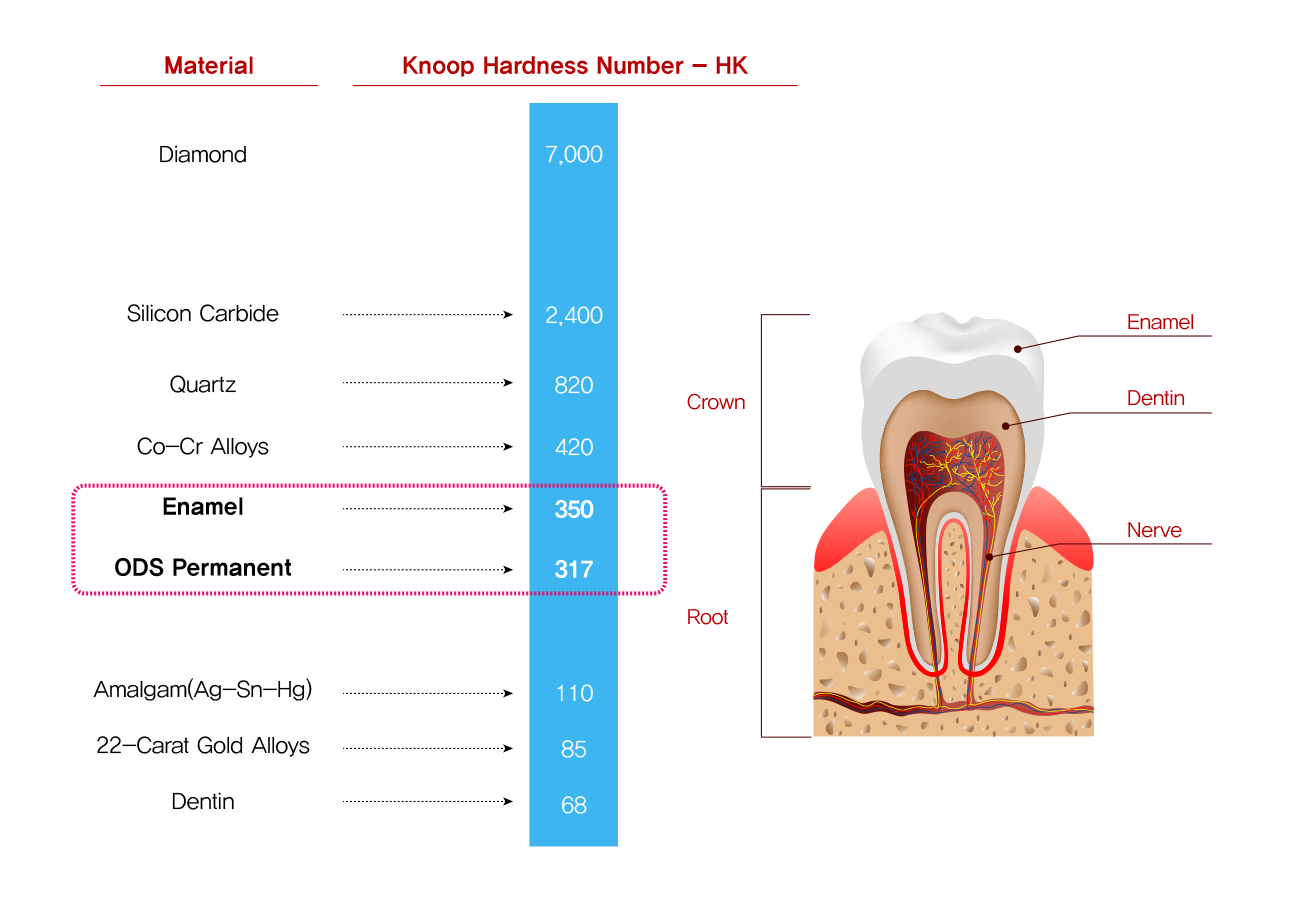

| Properties | Natural Teeth | ODS Permanent Resin | Remark |

| Compressive Strength | 285 kgf | 423.83 kgf | 148.7% |

| Knoop Hardnes | 350HK | 317 HK | 90.6% |

** ODS Permanent Resin : Single Crown with occlusal thickness of 2mm

2) Hardness comparison / Permanent (Single Crown)

Consideration for users – Small packaging(250g)

The 1kg of ODS Resin are packaged in small-capacity (250g) containers and opened by 250g each. Since the small-capacity packaging is not long in the consumption period and is convenient, ODS resins have a low risk of natural curing and is easy to use.

The total capacity (1kg) is exposed to UV rays in its natural state, and the risk of natural hardening such as chemical reaction and deformation is high, so the possibility of change of physical properties is high.

Even if it takes a lot of time and cost of injection and packaging, all products of ODS resin use a small amount(250g) of UV-blocking container for user convenience, so these have almost no possibility of physical property change.

Download the Reference PDF File

Related products

Subscribe to our newsletter and get “ODS Scan Cure”!

Subscribe to our newsletter and get “ODS Scan Cure”!

ODS RESIN